At our November TriCity Potters’ meeting we learned of Ilena Lee Cramer’s enthusiasm for Wild Clay. Most of us work with clay that has been processed and mixed to specific requirements and pugged, bagged and boxed for us. But Ilena is fascinated with the properties of locally found clay, here in BC. With funding from a unique artists residency from St andrews Wesley United Church in Vancouver Ilena has searched out sources of clay, particularly that which was used to make bricks for some well-known Vancouver buildings.

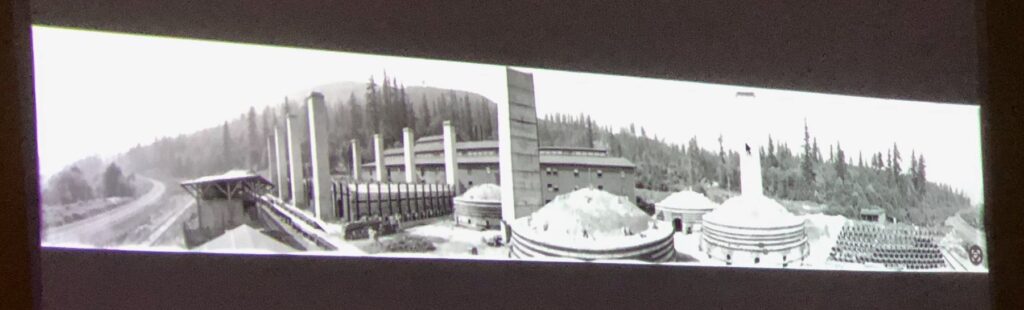

The presentation began with a slide show of the brickworks that existed here in the Lower Mainland. Sadly these closed long ago, as the extraction of clay became less profitable, although there are plenty of clay sites still to be found. Many bricks labelled Clayburn were made from Sumas mountain clay. Clayburn Village was built with locally made bricks and housed the factory workers. It is a tourist destination near Abbotsford today.

https://journals.lib.unb.ca/index.php/MCR/article/download/16988/22990?inline=1

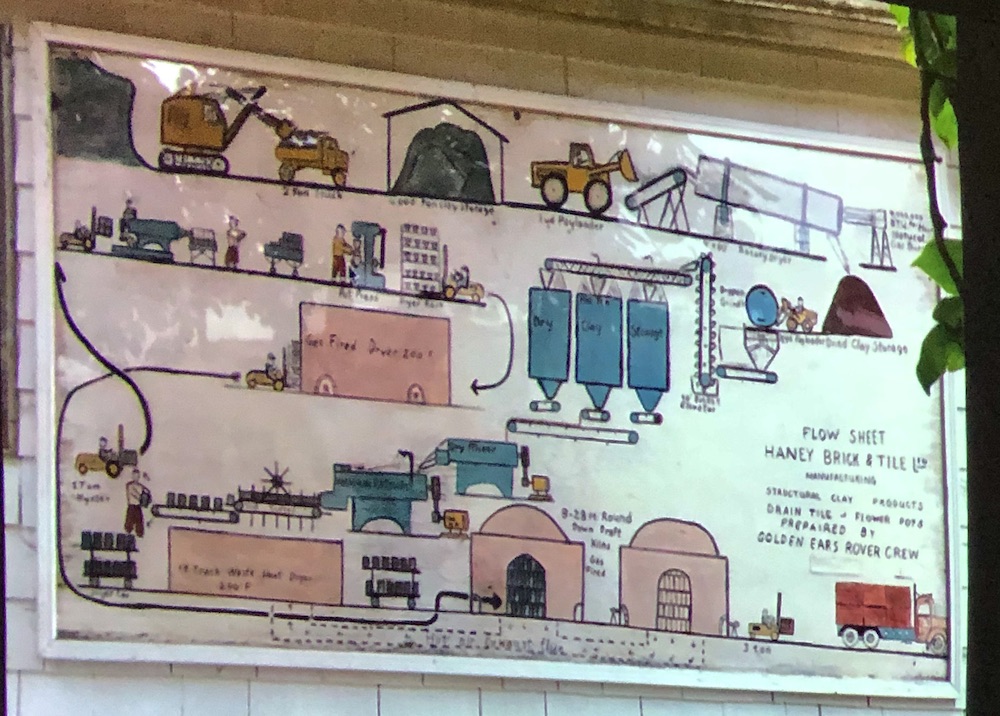

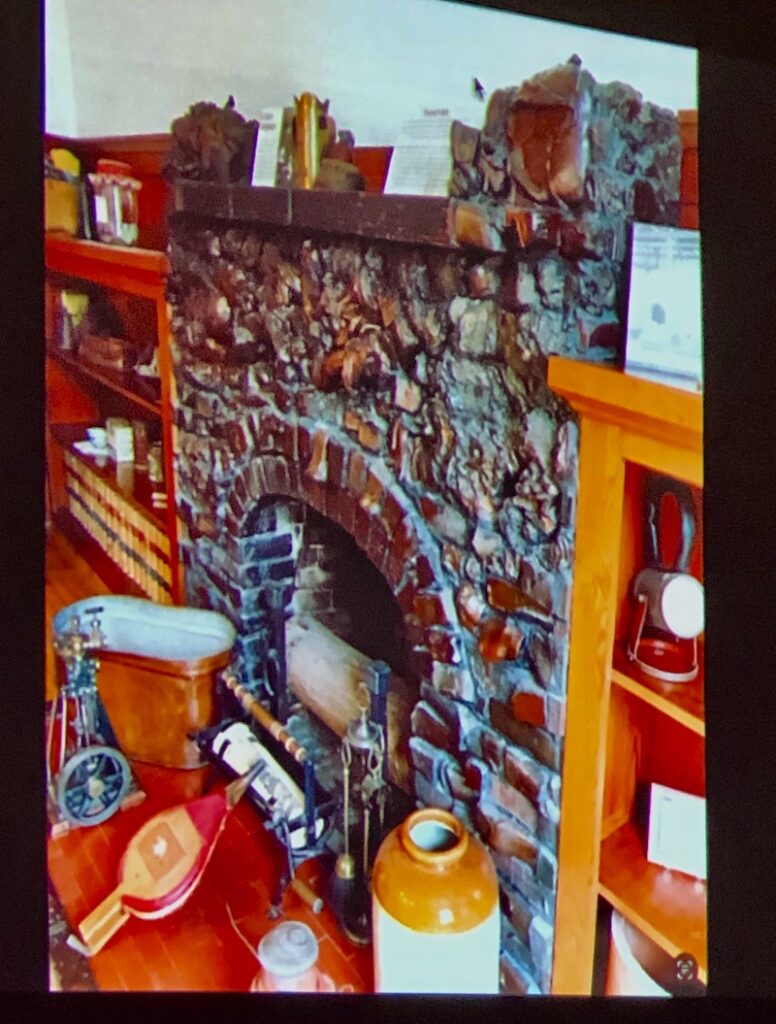

Another well-known brick factory was in Haney (Maple Ridge). Haney Museum, to be found next to Haney Bypass, was the clay mine manager’s house and sits at the base of the clay pit. We saw a photo of its fine fireplace, built with juicy klinker (almost melted kiln bricks). There’s a mural depicting the brick-making process on the back of the building.

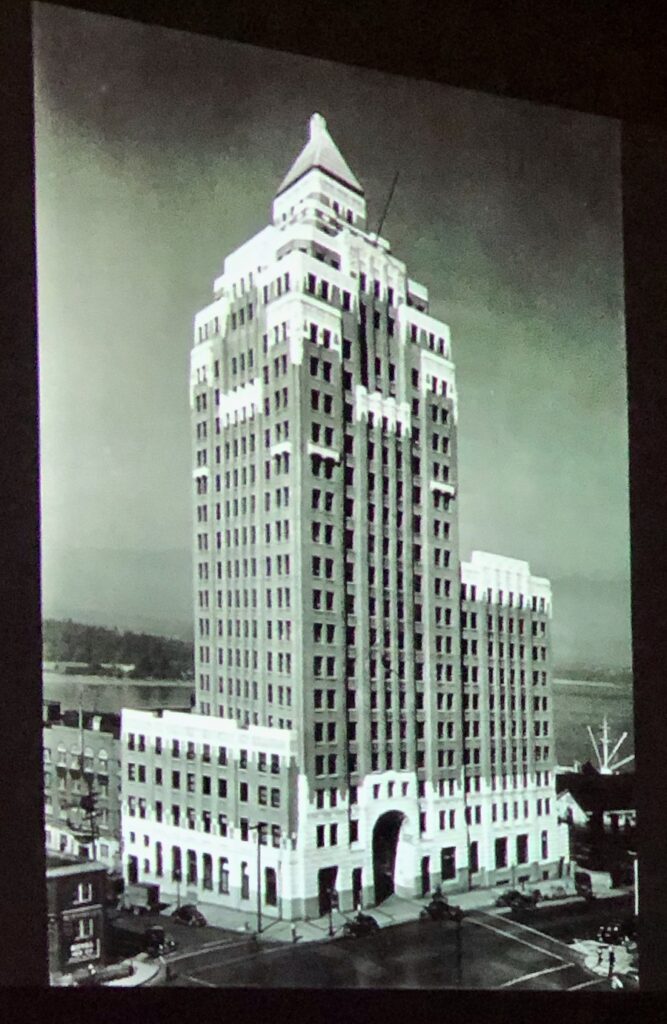

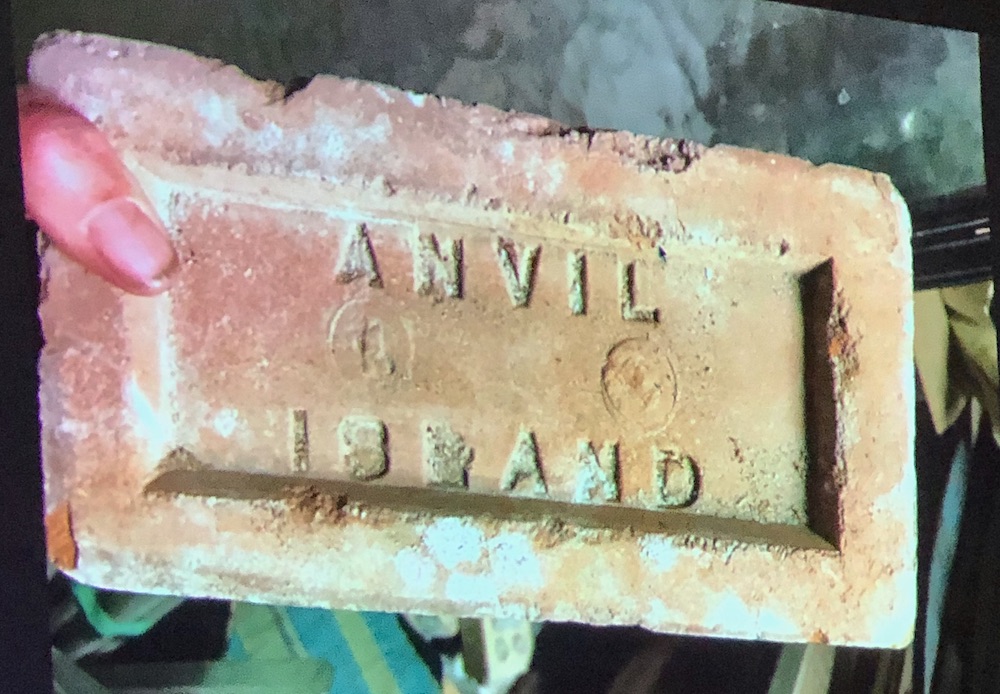

The Marine Building in Vancouver was built using Clayburn Brick. We also heard that there was a huge brickworks on Anvil Island in Howe Sound, where barges took bricks to the city.

Finally, Ilena was pleased to tell us about the Port Moody bricks found at the end of our Inlet. I believe more research will happen! For us clay fanatics the discussion of bricks and wild clay is fascinating.

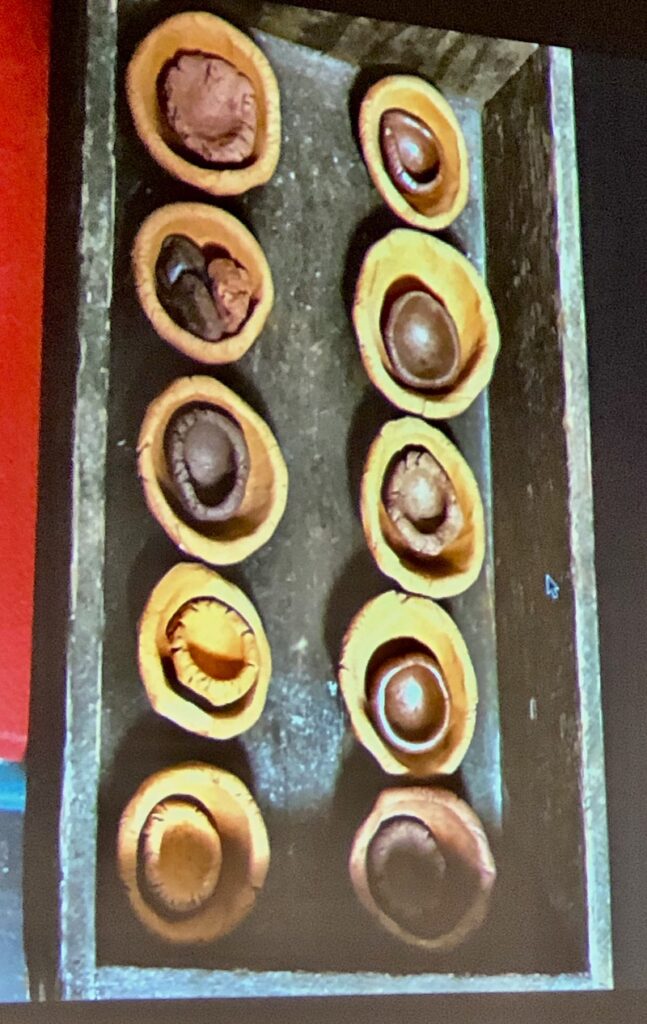

After a coffee break and a chance to consider some results of our October group soda firing, Ilena showed us slides and examples of how to research the properties of found clay. It’s important to set a small pinch pot of said clay in a bisqued pot made of more refractory clay. These tests then reveal what temperature the clay needs to be fired at to reach vitrification.

Thank you for an interesting presentation, Ilena, and the chance to see examples of your studies. I’m sure several members will be on the look out for and experimenting with local clay.

Alan and I are looking forward to welcoming TriCity Potters to our annual Christmas party next week.